recycled hats. By using rPET fibers in the manufacture of hats, it is possible to recycle plastic bottles. Recycled hats are lightweight, comfortable and moisture wicking, making them ideal for outdoor sports, travel and everyday use.

In today’s increasingly environmentally conscious society, recycling has become an important initiative to protect the planet. Plastic bottles are one of the most widely used plastic products in our daily lives, and the large amount of plastic bottles often becomes one of the main sources of landfill or pollution of the ocean. However, by recycling plastic bottles and turning them into eco-friendly items, we can minimize the environmental impact of plastic waste.

Particularly in the hat industry, recycled products have great potential to promote and encourage the use of environmentally friendly materials to their fullest advantage.

First, let’s understand the definition and difference between rPET and PET.

- PET stands for polyethylene terephthalate and is a common plastic material widely used in the manufacture of plastic bottles and other packaging containers.

- rPET stands for recycled polyethylene terephthalate, which is a material obtained by recycling and reprocessing discarded PET products.

Compared to virgin PET, rPET has a lower carbon footprint and environmental impact because it reduces the need for new plastic materials and saves energy and resources.

Why do we recycle PET?

First, recycling PET reduces the accumulation of plastic waste and pollution of the environment. Recycling plastic bottles and processing them into rPET reduces the load on landfills and reduces the exploitation of natural resources. Second, recycling PET can also save energy. Manufacturing new plastic materials requires large amounts of oil and energy, and by recycling PET, we can save these resources and reduce carbon emissions. In addition, recycling PET offers great potential for the economy, creating jobs and promoting sustainable development.

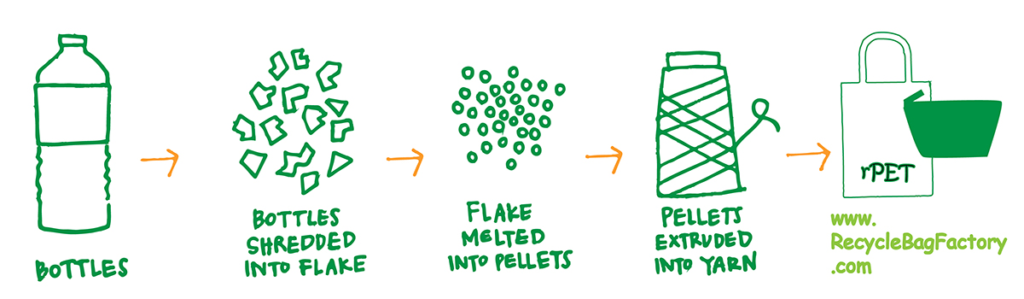

How is rPET made?

The process of recycling PET can be briefly summarized in the following steps. First, the plastic bottles are collected and sorted to ensure that the recycled PET can be processed efficiently. Next, the PET bottles are shredded into small pellets called “shreds” through a process of cleaning and removing impurities. The shredded material is then heated and melted into a liquid form of PET, and finally, the liquid PET is cooled and molded to produce a recycled plastic product called rPET.

The relationship between rPET and plastic bottles.

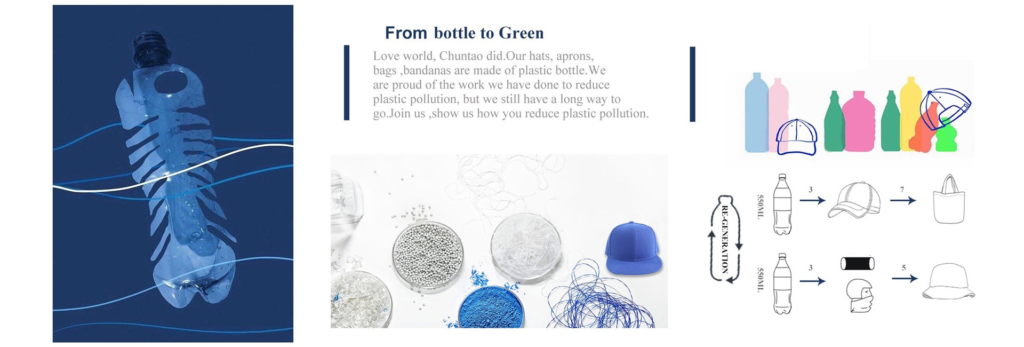

By recycling plastic bottles and making them into rPET, we can reduce the production of plastic waste, reduce the need for new plastics, and contribute to environmental protection.

In addition, rPET has many advantages and impacts. First, it has good physical properties and plasticity, and can be widely used in the manufacture of plastic products. Secondly, the production process of rPET is relatively environmentally friendly and can reduce energy consumption and greenhouse gas emissions. In addition, rPET can be recycled and used, reducing the negative impact of plastic waste on the environment.

When plastic bottles are recycled, they can be made into many eco-friendly products, including recycled hats, recycled T-shirts and recycled handbags. Made from rPET, these products have many laudable effects, benefits and sustainable advantages that have a significant impact on protecting the environment and promoting sustainable development.

First up is recycled hats. By using rPET fibers in the manufacture of hats, it is possible to recycle plastic bottles. Recycled hats are lightweight, comfortable and moisture wicking, making them ideal for outdoor sports, travel and everyday use. They not only protect the head from the sun and the elements, but also bring style and environmental awareness to the wearer. The production process of recycled hats reduces the need for new plastic, reduces energy consumption and carbon emissions, and has a positive impact on reducing plastic waste and protecting the environment.

The incorporation of rPET into creating these sustainable goods not only diminishes plastic waste but also conserves energy and cuts down on greenhouse gas emissions. These versatile products suit diverse settings, blending eco-consciousness with style. Embracing these items heightens environmental awareness, advocates for sustainability, and effectively curbs plastic waste.

Recycled hats, T-shirts, and handbags are eco-friendly items crafted from recycled plastic bottles, featuring rPET material. Comfy, durable, and adaptable to any occasion or season, they embody sustainability. Championing their production and adoption curbs plastic waste, lowers energy use, and aids environmental safeguarding. By advocating these choices, we advance personal well-being and planet care, working collectively towards a cleaner, sustainable tomorrow.

2 回复

jti208

Thanks for the link. I’ll check it out!